On Long Island, concrete moisture problems are often blamed on coastal air, groundwater, or seasonal humidity. But every slab in every region contends with moisture from the moment it is poured. The real issue is whether a polyurea garage floor coating system is designed for moisture mitigation, or installed with the expectation that moisture can be blamed later, voiding warranties.

How the Polyurea Moisture Meter Gets Used After Failure

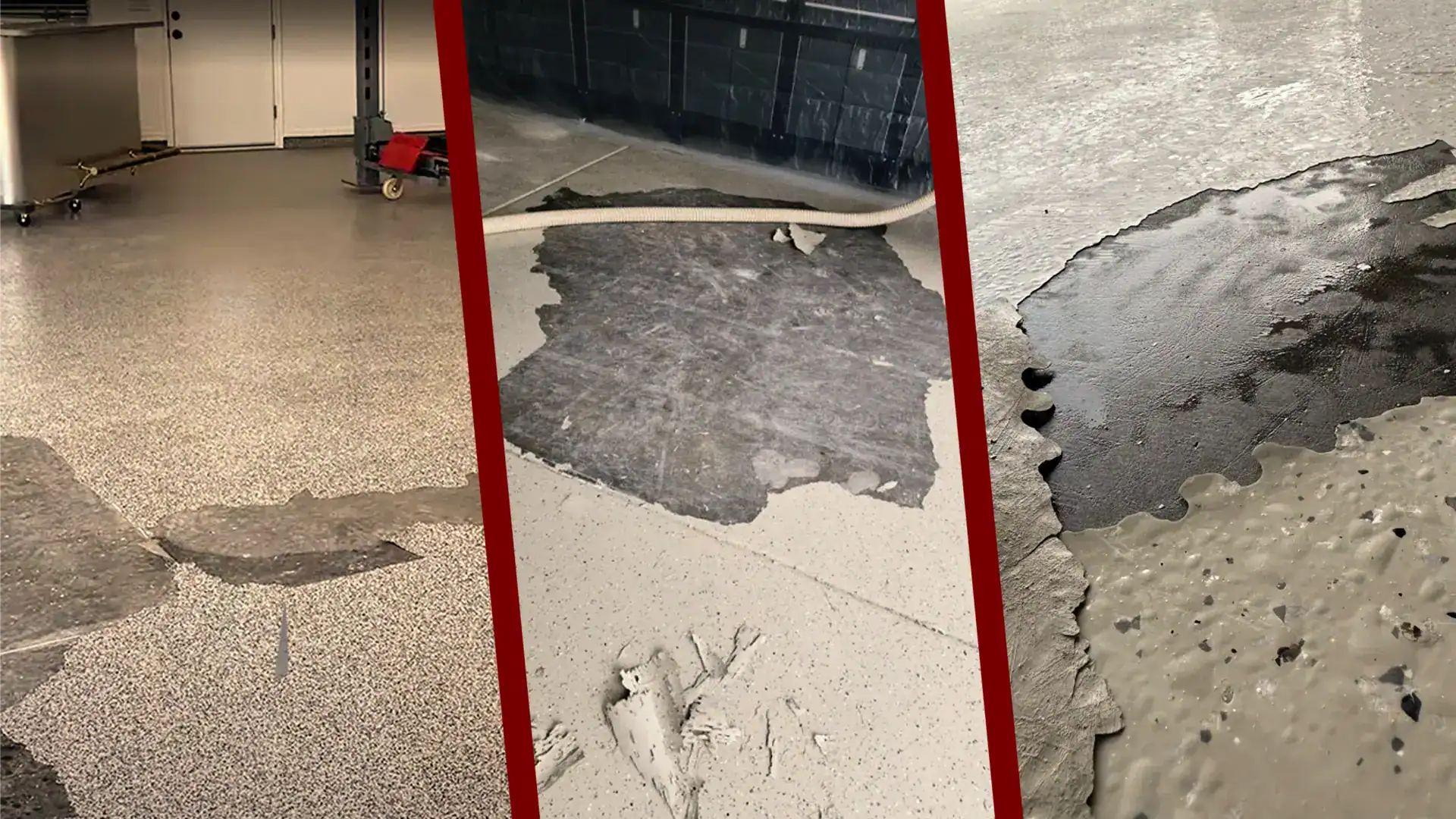

Many 1-day garage floor coating installers treat moisture like a post-install discovery. When a coating blisters or peels, a moisture meter suddenly appears. A reading is taken directly at the failure point, where vapor pressure is highest, and that number is used to deny the warranty.

What rarely exists is documented testing before installation. Moisture did not appear after the floor failed. It was already present in the slab and never properly addressed.

Why Speedy Polyurea Installations Struggle Long-Term

A typical 1-day install relies on fast-curing polyurea or polyaspartic primers applied directly to concrete. These products make quick turnaround possible, but they do not provide true moisture mitigation.

Fast cure is not vapor control. Without a moisture-mitigating base coat, Moisture Vapor Transmission pushes upward through the slab. On Long Island, groundwater levels, rainfall, and seasonal changes keep vapor pressure active year-round. When that pressure meets a coating system that cannot manage it, blistering, peeling, and delamination follow.

How Our Garage Floor Coating Systems Address the Issue Upfront

Timeless Concrete Coatings installs garage floor coating systems built around moisture mitigation from the start. We begin with an industrial, 100% solids epoxy primer engineered to manage Moisture Vapor Transmission and create a chemically bonded foundation within the slab.

From there, decorative flakes are broadcast across the floor for texture and strength, followed by dual polyaspartic clear coats for durability, UV stability, and easy maintenance. This approach requires a professional 2-day installation so each layer performs its role properly.

Before committing, explore colors and flake blends using our Live Coatings Visualizer to see how a professionally installed system can look in your garage. Then schedule a consultation with Timeless Concrete Coatings and choose a system built on concrete science, not excuses.