In Long Island, Timeless Concrete Coatings specializes in durable, stylish epoxy flooring solutions for homes and businesses. Here’s a breakdown of common epoxy flooring terms used in the industry to help you understand your options.

Epoxy Flooring Terms: Types of Coatings

These terms explain the different types of coatings, giving you a better understanding of each performs in Long Island’s climate.

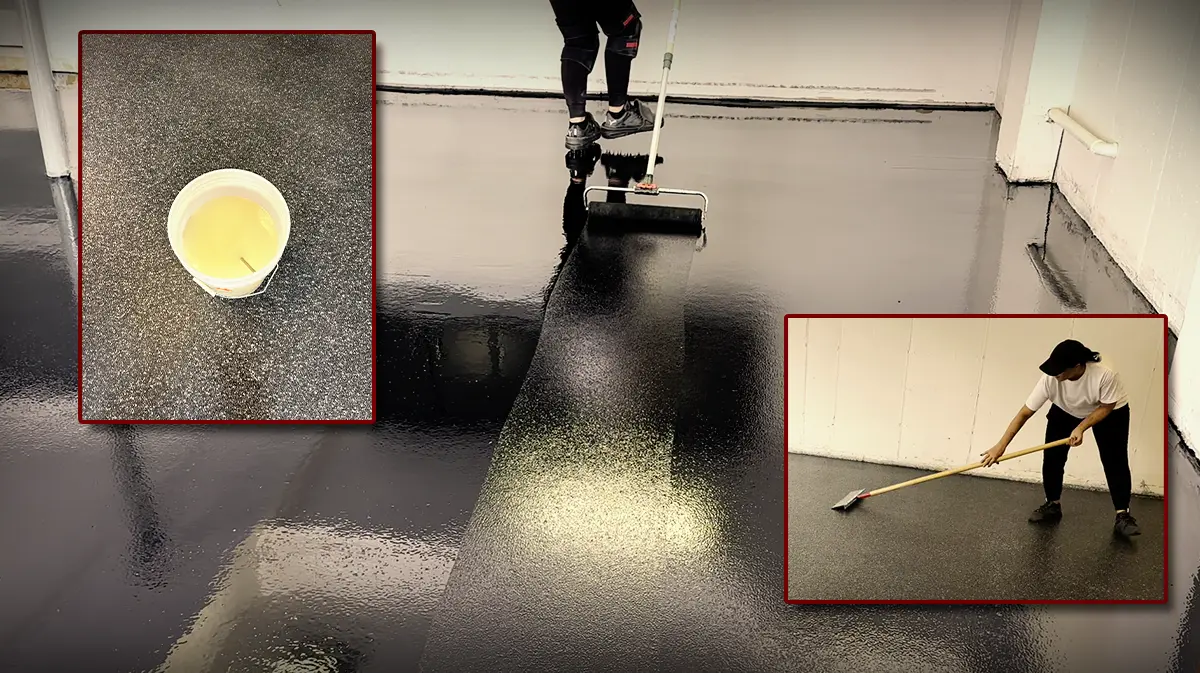

- Epoxy Coating: A robust, chemical-resistant coating created when its Part A resin is mixed with its Part B activator. Epoxies are “high-build” coatings; that is, they can go down very thickly. In addition, they’re slow-curing (relative to polyurea-polyaspartics). But the high-build, slow-cure properties make it an excellent moisture vapor barrier. That is, when applied direct-to-concrete, this thick coating resists moisture vapor transmission (MVT) and the resulting high hydrostatic pressure better than any other coating type. So epoxies (specifically, moisture-mitigating epoxies) are excellent primer coats in garages, basements, and commercial spaces exposed to medium to high moisture in the concrete. Epoxies do have a bad habit of fading when exposed to sunlight. So, if used as a color coat or top coat, they are best suited for interior installs. However, in Long Island, where humidity and saltwater can wreak havoc on floors, using a moisture-mitigating epoxy as primer offers the best protection for garages and basements.

- Polyaspartic Coating: Polyaspartics (aliphatic polyureas) are fast-curing, UV and chemical resistant coatings. They prevent yellowing and fading when used as topcoats for Long Island’s outdoor spaces. But they can only be applied thinly (they are not “high-build” coatings) and cure so fast in the presence of moisture that they fail to properly penetrate concrete. That is, they’re superb top coats, but not so good primer coats. (Because coating systems consist of multiple layers of coatings, the best systems use an epoxy as primer with one or more polyaspartic topcoats.

- Moisture Mitigation: Given Long Island’s humid climate, moisture mitigation is key to preventing bubbling or peeling. Applying a moisture vapor barrier (i.e., a moisture-mitigating epoxy primer) is critical! By controlling moisture, epoxy floors remain durable for a long time.

Epoxy Flooring Terms: Basics

Homeowners and business owners alike often use these terms when referring to epoxy flooring in more casual contexts.

- Garage Floor Coating: A term often used to describe epoxy and polyaspartic coatings applied in layers to protect garage floors. In Long Island, these coatings are essential to shield concrete from damage due to moisture infiltration (from below and above), salt, automotive fluids, and vehicle traffic.

- Concrete Paint: Frequently used to refer to epoxy coatings, but unlike paint, epoxy forms a solid, protective bond with concrete. This term is common among homeowners looking for durable, long-lasting solutions.

- Flake System: A flake system incorporates decorative thermoplastic (or mica) flakes into the coating system. The flakes are broadcast into the “wet” epoxy primer coat and become embedded. Flakes create depth, texture and visual interest…and add some slip resistance. Flake systems are the most durable of coating systems with the longest warranties…particularly important for Long Island’s wet, coastal conditions.

Concrete Coating Components

The ingredients that make up epoxy and polyaspartic coatings play an important role in their durability and aesthetic appeal. Here are a few terms you may have heard that warrant a bit of explaining.

- Resin: The primary component of epoxy that binds to concrete, creating a strong, protective surface.

- Hardener: The catalyst that cures the epoxy, turning the liquid resin into a solid, durable floor.

- Mica Flakes: Natural stone flakes added to the epoxy for a reflective, shimmering finish. These are popular in Long Island for their high-end, luxurious appearance.

Conclusion

Timeless Concrete Coatings provides Long Island residents with epoxy and polyaspartic floors designed to last in coastal and humid environments. Whether you’re looking to protect your garage, basement, or outdoor space, understanding these key terms ensures you can make the right choice for your floor. From moisture mitigation to decorative flake systems, you’ll be prepared to choose a coating that fits your style and needs.