Comparing epoxy and garage flooring options on Long Island can be confusing if you’re not familiar with the terminology. This cheat sheet breaks down the key terms you’ll see so you can make an informed decision.

Epoxy Coatings

Epoxy is a two-part material made by blending a resin and hardener, which then cures into a dense, highly adhesive coating. In professional garage flooring systems, a moisture-mitigating epoxy forms the primer coat because it cures slowly, penetrates deeply, and bonds strongly with concrete slab. It creates the structural base needed for long-term durability.

Moisture Mitigation

Concrete emits moisture vapor continuously. Without moisture mitigation, garage flooring can bubble, peel, or fully delaminate. The solution involves applying a moisture-mitigating epoxy primer that acts as a vapor barrier. 1-day installers often skip it (in pursuit of speed), while 2-day systems include it for lasting adhesion.

Concrete Paint

Despite similar marketing language, concrete paint is not a coating. It’s a thin, cosmetic layer that sits on the surface rather than bonding into the concrete. It cannot handle hot tires, moisture, or seasonal shifts and typically wears or peels quickly. It’s inexpensive, but not built for performance.

Polyaspartic

Polyaspartic is a UV-stable, fast-curing clear topcoat known for its resistance to stains, chemicals, and abrasion. It protects the decorative layers beneath it and prevents yellowing. While some companies promote all-polyaspartic systems, polyaspartic performs best when paired with an epoxy base coat that provides proper moisture mitigation.

Polyurethane

A clear coat option used in some coating systems. Polyurethane is durable but tends to offer lower UV and chemical resistance than polyaspartic—an important distinction for garages that may see sunlight and fluctuating temperatures.

Flake/Full-Flake

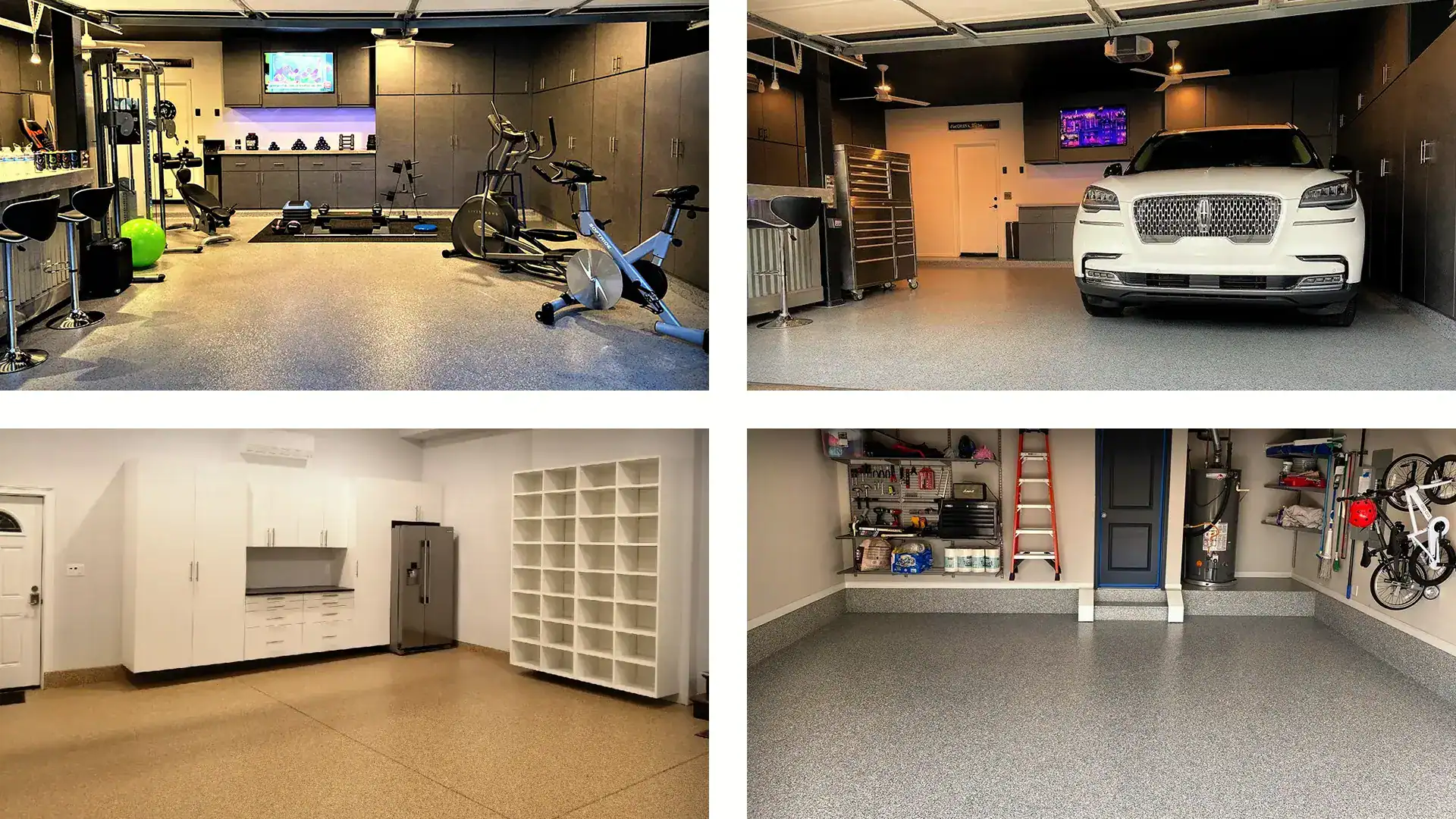

In a flake epoxy floor system, colored polyvinyl acetate (PVA thermoplastic) and/or mica mineral flakes are broadcast into the epoxy layer while it’s still wet to add traction, color, and depth. A full-flake coating covers the entire surface, creating a thicker, more uniform finish that enhances durability—ideal for high-use Long Island garages.

Garage Floor Coating

A multi-layer system consisting of a moisture-mitigating epoxy primer, full-flake coverage, and a polyaspartic topcoat. Together, these layers create durable, seamless garage flooring engineered for long-term protection and visual appeal.

Waterproofing Basements

Long Island homeowners often face groundwater pressure and moisture intrusion. Our process involves sealing the concrete slab to prevent vapor penetration….controlling moisture at the source.

Want garage flooring built for Long Island’s coastal climate? Timeless Concrete Coatings delivers premium, long-lasting installations designed to perform. Contact us today for a free quote.