The Problem: Garage Floors That Peel and Crack Too Soon

Long Island homeowners are used to dealing with wet seasons, coastal air, and temperature swings—but they don’t expect their garage flooring to fail because of it. Unfortunately, many coatings begin to peel, bubble, or stain just a year or two after installation. Some even crack after a rough winter.

When the floor breaks down this early, the issue usually isn’t on the surface—it’s coming from underneath.

The Cause: Moisture-Vapor Transmission Below the Surface

Concrete absorbs moisture from the ground, especially in humid and coastal areas like Long Island. That moisture then rises through the slab in vapor form—a process called moisture-vapor transmission (MVT). If your garage floor coating doesn’t stop that vapor from reaching the surface, damage is inevitable.

On Long Island, that damage is made worse by:

- Salt exposure from winter road treatments

- Freeze-thaw cycles that stress the slab

- Humidity that raises the moisture content in the ground

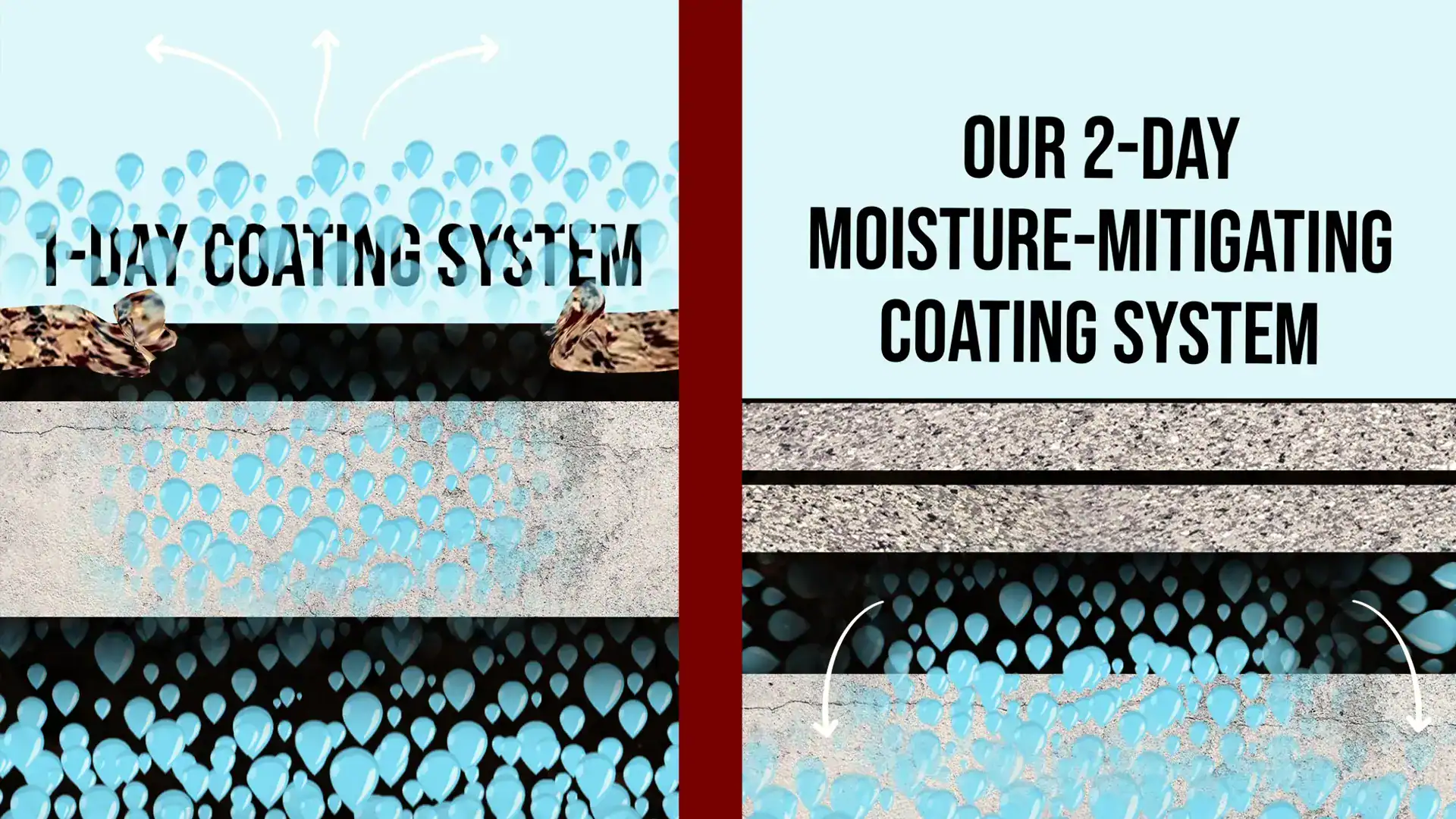

The problem? 1-day garage flooring systems don’t block vapor effectively. These systems use a polyurea or polyaspartic as both the direct-to-concrete base coat and single topcoat. While these coatings are superb top coats, they’re lousy base coats. In the presence of medium to high moisture, they cure crazy fast. So fast, in fact, that they simply don’t have time to deeply penetrate the concrete slab. Additionally, these coatings can only go down thinly (unlike a high-build epoxy). So the wafer-thin, poorly-penetrating polyurea-polyaspartic base coat just can’t hold up as a moisture vapor barrier. Over time, vapor pressures can lead to peeling, efflorescence, or even contribute to surface cracking.

The Solution: Timeless Concrete Coatings’ 2-Day System with True Vapor Control

Timeless Concrete Coatings (Long Island) installs a proven 2-day garage flooring system, designed to block MVT and resist the salt, moisture, and seasonal shifts unique to coastal climates.

The key is a thick, 100%-solids, moisture-mitigating epoxy base coat that deeply penetrates and bonds with the concrete. This slow-cure coating cures overnight to create a thick moisture vapor barrier. We return on day 2 to apply two (not just one!) 100%-solids polyaspartic topcoats for durability, UV resistance, chemical and stain resistance, and a polished, easy-to-clean finish.

The Timeless Advantage:

- Moisture-mitigating epoxy base coat = true moisture mitigation

- Overnight cure = deep penetration and full adhesion for long-term protection

- Dual polyaspartic topcoats = built-in resistance to salt, chemicals, and wear

Upgrade to Garage Flooring That’s Ready for Long Island Living

From humidity and salt to snow and freeze cycles, Long Island conditions are tough on concrete. Timeless Concrete Coatings delivers garage flooring that stands up to it all—by blocking moisture at the base and sealing strength into every layer.

Contact Timeless today to schedule your free quote and invest in a garage floor that’s built for your environment—and built to last.