In Long Island homes where space is precious, the garage often pulls double duty—as a car bay, storage room, and workshop all in one. But if you’re still working on a plain concrete floor, you’re making projects harder than they need to be.

Before: A Frustrating Workshop Experience

A bare concrete floor might seem like a blank slate, but in practice it creates a host of problems:

- Dropped tools chip the surface, and the cracks only grow

- Every oil stain, paint drip, or solvent spill becomes a permanent scar

- Concrete dust gets everywhere—on tools, projects, even your lungs

- Hot tires from your daily driver or project car leave black marks

- Moisture creeps up through the slab, especially during Long Island’s rainy season, creating all sorts of moisture-related issues

Without proper garage flooring, your workshop becomes a constant clean-up zone—not a space for creativity or focus.

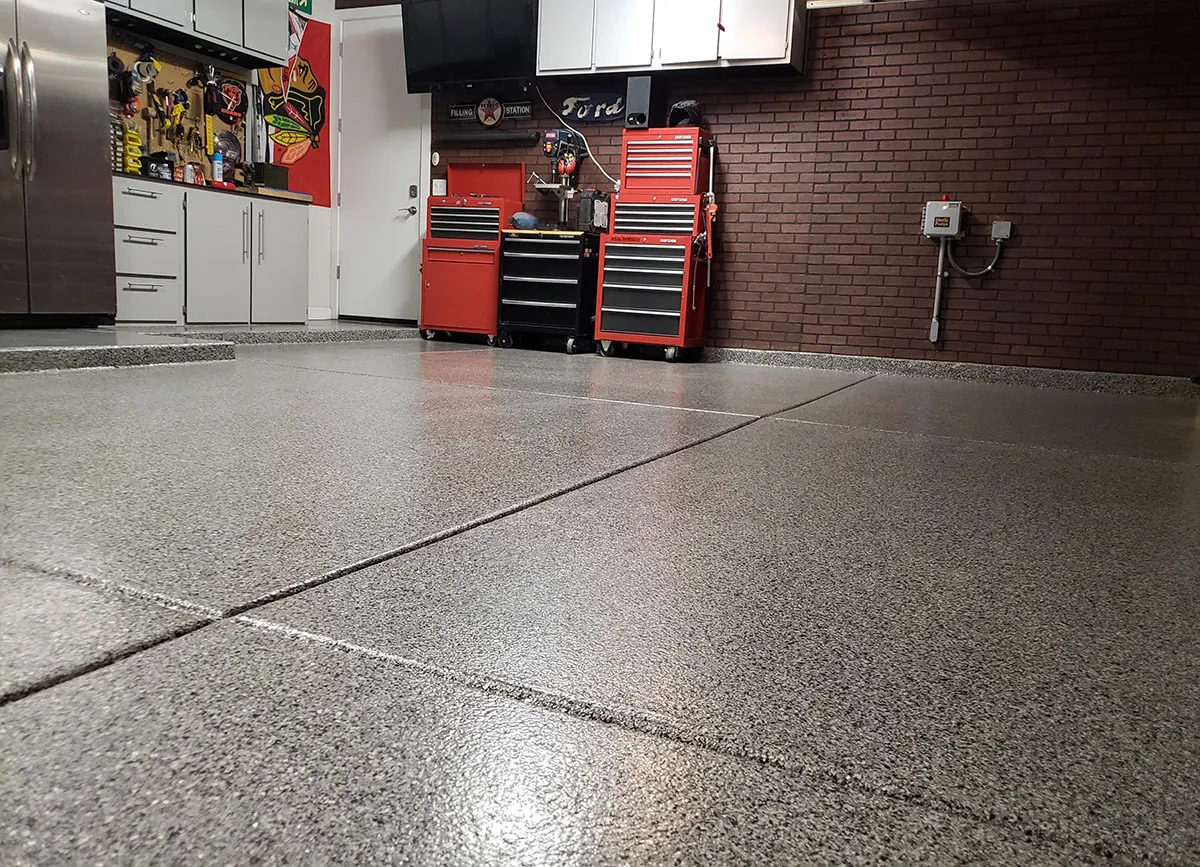

After: Garage Flooring That Elevates the Way You Work

Timeless Concrete Coatings installs hybrid epoxy and polyaspartic garage flooring, designed specifically for homeowners who use their garages as functional, high-performance workspaces.

- Impact resistance protects the floor from dropped hammers, heavy saws, or car parts

- Chemical resistance means that spills wipe up easily without staining or damaging the finish

- Anti-skid texture adds grip, helping you stay steady even during messy jobs

- Moisture mitigation keeps your space dry from the ground up, no matter the weather

- No hot-tire transfer, so you won’t see those stubborn rubber marks even after long drives

Now your garage can handle every build, repair, or restoration you throw at it—with less mess and more control.

The Long-Term Power of the 2-Day System

Timeless Concrete Coatings doesn’t rush through installs. Instead, they rely on their proven 2-day installation system (quality over speed):

- Day 1: Concrete grinding and repairs to cracks, pitting and breaks.

- Day 1: Application of the slow-curing, 100%-solids, moisture-mitigating epoxy base coat as the moisture vapor barrier.

- Day 1″ Broadcasting of the selected flake blend into the “wet” base coat.

- Day 2: Application of 2 separate 100%-solids polyaspartic topcoats for strength, UV protection, and long-term durability

The result is garage flooring that looks sleek, performs under pressure, and supports your projects for years to come.

Build the garage workshop you’ve always wanted—starting with better garage flooring. Contact Timeless Concrete Coatings on Long Island today to schedule your free consultation.