When contractors in the garage floor coating system industry talk about “concrete prep,” it’s not just a superfluous step done for its own sake. It’s the step that determines whether a coating will hold tight for years or fail within months. It’s the equivalent of cleaning and wiping down a glass surface before applying a sticker. Without that “prep,” that sticker will be peeling in no time.

Concrete prep means mechanically altering the floor so that the primer coating bonds properly, and it’s as essential for residential garages as it is for commercial flooring projects.

The Best Tool for the Job

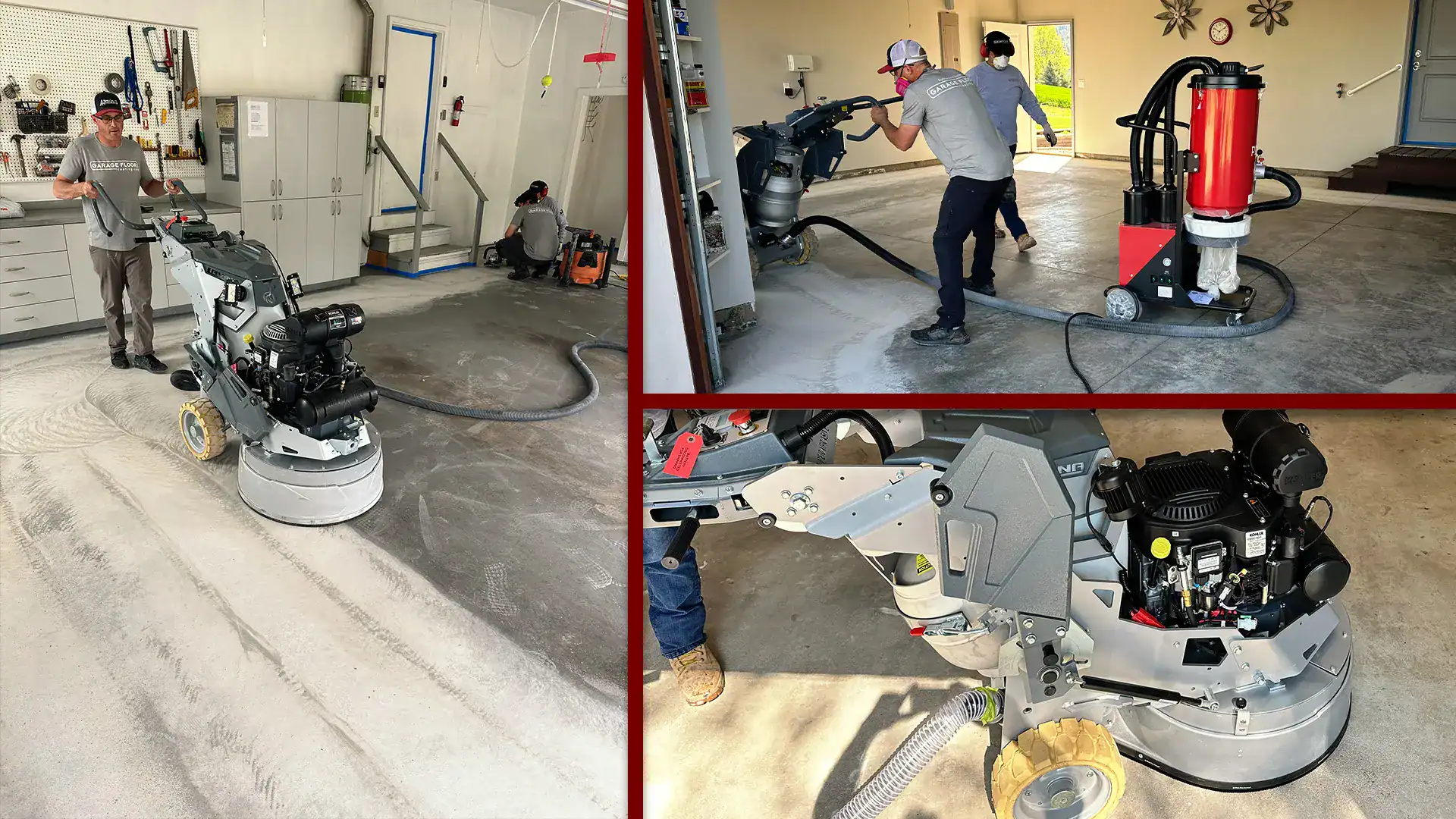

At Timeless Concrete Coatings, we rely on propane grinders for this job. They’re powerful, fast, and efficient, capable of covering large areas while producing a consistent surface. Unlike electric grinders, propane models aren’t tethered to cords and don’t bog down on big spaces.

They’re also safer than people often assume. Propane has a high ignition point and narrow flammability range, and these grinders produce near-zero exhaust, making them safe to use even indoors.

It’s a tool that delivers both performance and peace of mind.

Tools to Stay Away From

Other methods might seem easier, but they don’t work for long-term results:

- Acid etching and low-pressure water jetting leave the concrete too smooth, which causes coatings to peel.

- Aggressive techniques like sandblasting or rotomilling leave the surface unnecessarily rough for garages.

- Even electric grinders, while cheaper, are underpowered and slow compared to propane units.

None of these options achieve the consistency needed for a strong garage floor coating system.

Grinding Toward the Right CSP

Every bit of grinding has one goal: achieving the right Concrete Surface Profile (CSP). This scale ranges from 1 to 10, with 1 being slick smooth and 10 being overly rough. For concrete coating systems in garages, the target is a CSP of 3–4. This range creates a balanced texture that allows the coating to bond securely without damaging the floor. It’s the Goldilocks zone—“just right” for lasting adhesion.

Why Shortcuts Don’t Last

DIY kits and one-day garage floor coating solutions rarely deliver proper surface prep. They skip the grinding or use weak methods that don’t reach the correct CSP. The result? Coatings that peel, bubble, or crack under everyday wear—especially with the moisture and stress that garages naturally see.

At Timeless Concrete Coatings, we don’t cut corners because prep is the foundation of a floor that lasts. Call or email us today to learn how the right preparation leads to a garage floor coating you’ll enjoy for years to come.